- researchPlastics

- Resources

Resources

Plastics Economy

Plastic is everywhere. It is ubiquitous and remains among the most commonly used materials in modern times due to its low production cost and unique properties. The invention of the material dated back to the late 1800s, with the first plastic synthetic produced in 1907, known as Bakelite. Plastics are made up of polymers, with a combination of chemical additives. Most are produced from fossil fuels such as oil and natural gas, while a minimal percentage of variants are produced from renewable sources or bio-based (plant) such as corn and sugarcane derivatives.

Due to the unique properties, plastics have been put to extensive use and numerous functions in a numerous products and applications. These properties include strength, moldability, durability, light weight, liquid impermeability, corrosion resistance, and thermal insulation. The applications of plastics cut across several sectors including transportation, automobile, packaging, health, agriculture, textile furniture, electronics, and construction.

Over the years, the plastic industry has witnessed growth and development, making tremendous contributions to the world economy. The rates of production and use of plastics in the last two decades have doubled, with projection to triple by 2060 (OECD, 2022b), thus reflecting the success of plastic material. The global production of plastics was approximately 390.7 million tonnes in 2021 (PlasticsEurope., 2022).

Regrettably, the proliferated and unsustainable production and use of plastics, combined with the poor management of the subsequent waste, are contributing to the accumulation of waste in landfills, widespread pollution and other negative impacts on human health, biodiversity, and the environment.

Circular Plastic Economy

The life cycle of plastic, which includes the production, use, and end-of-life, are known to be associated with several problems. The unsustainable production and use of plastics, combined with the poor management of the subsequent waste, are contributing to the accumulation of waste in landfills, widespread pollution and other negative impacts on human health, biodiversity, and the environment.

This scenario calls for a shift from the linear economy of produce, use and discard to a more sustainable and circular model for plastics. The linear model represents not only significant loss of resources, but a continued destruction to the environment. Therefore, rethinking and redesigning the plastic economy is crucial. Circular plastic economy provides a promising opportunity where plastic waste are diverted from the landfill to a better and more sustainable plastic waste economy.

Circular economy (CE) is a concept that centers on the principles of the waste management hierarchy and promotes the circulation of materials or products in closing the loops. The application of CE to plastics supports a broader plastic framework that changes direction on the general use of plastics and the management of the corresponding waste, to the promotion of options higher up the waste management hierarchy. The framework foremost aspect should be fundamentals that prevents plastic waste from occurring in the first place, particularly through sustainable product design. Innovative and sustainable product designs allow plastic products to be reused, repaired, refurbished, remanufactured, repurposed and recycled, in line with an extended waste management hierarchy.

The circular plastic economy is immensely beneficial as it helps in reducing the environmental burden of plastics while retaining their usefulness and value. The quantity or frequency of extraction and use of plastic resources for production are reduced, and consequently, the mass of plastic waste generated and disposed into the ecosystem is minimised. It also contributes to the mitigation of environmental plastic pollution and limits the emissions of poisonous gases and substances such as carbon monoxide, acid gases and heavy metals into the atmosphere.

Plastics Value Chain

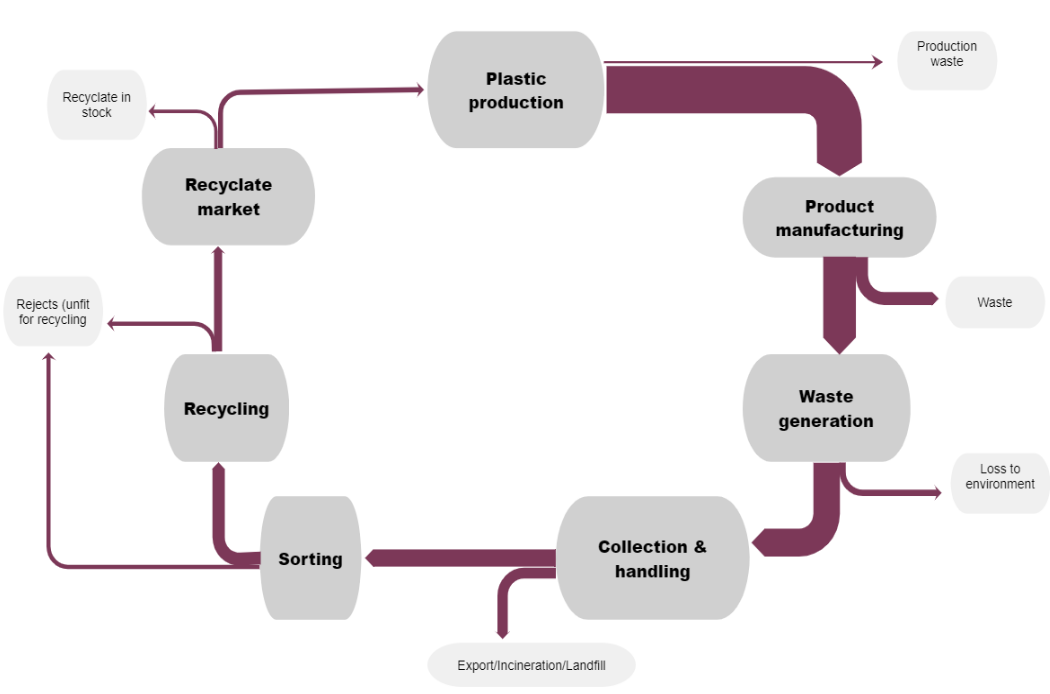

The plastic value chain is a complex system that impacts almost every industrial sector, if not all. Every stage of the value chain – from the raw materials extraction for the production of plastics to the final plastic waste management – plays a critical role in the well-being of the system. The figure illustrates the sequence and networks of the different stages of the value chain, and also, the flow of plastics along the chain.

Figure of plastics value chain (Olatayo et al., 2023)*

The various stages include primary plastic production, product manufacturing, product consumption, plastic waste collection, sorting, and recycling (Olatayo et al., 2023)*. Making informed decisions relating to resource efficiency and optimisation, waste reduction, and environmental sustainability is crucial, andclosely tied to a good knowledge of the value chain.

⦿ Primary plastic production is the initial stage of the value chain. It involves processes such as extracting the resources and converting chemical components into olefins. Primary plastics include polyethylene terephthalate (PET), high-density polyethylene (HDPE), polyvinyl alcohol (PVC), low-density polyethylene (LDPE), polypropylene (PP), polystyrene (PS) and others (acrylonitrile-butadiene-styrene ABS, styrene acrylonitrile SAN, polyamide PA, etc.).

⦿ Plastic product manufacturing accommodates the conversion of primary plastics into finished plastic products. Processes occurring in this stage include extrusion, injection moulding, blow moulding, and thermoforming. The product consumption stage represents the various industrial sectors making use of plastic such as healthcare, packaging, construction, textile, furniture, and automobile. Regrettably, a significant share of plastics consumed annually becomes waste.

⦿ Plastic waste collection is a very important component of the value chain, considering its core role in plastic waste management. It involves the collection and transport of waste from households and businesses. Different collection schemes in existence include kerbside (door-to-door), central (bring-to sites or communal collection), drop-off and buy-back. The informal sector is a major actor in waste collection in developing economies.

⦿ Sorting stage is critical to plastic waste recycling, considering its impact on recycling quality. The process can either be manual or technological, using the near infrared (NIR). It is affected mainly by plasticwaste composition.

⦿ Recycling of plastic waste is largely through mechanical and chemical processes, while the biological process is emerging. The quality level of recycling is affected by various factors such as plastic types, properties, designs, colour, and polymer mixture. Challenges in this stage can lead to down-cycling, where the quality of the recycled plastic is lower compared to the initial plastic material or product being recycled.

* Olatayo, K.I., Marnewick, A.L., Mativenga, P.T. (2023). Plastic value chain and performance metric framework for optimal recycling. Journal of Industrial Ecology, 1–23. https://doi.org/10.1111/jiec.13384

Plastic protect and preserves our food and drinks

Plastic packaging is the most consumed application of plastic, representing approximately 26% of plastics consumed globally (Ellen MacArthur Foundation, 2017)*. Plastic is of significant and numerous benefits in the packaging industry. It helps extend food shelf life, make possible important health applications, enable lighter and safer shipping, and reduce emissions.

Figure of different plastic packaging

Plastic particularly revolutionises the food and beverage industry by preserving foods in suitable eating conditions for an extended period of time. Food is shielded from damaging external physical, chemical, and biological sources. This prevents infections and preserves its freshness, taste and nutritional value.

Additionally, plastic packaging offers an ideal solution for the reduction of food waste, as substantial mass of food annually becomes waste globally. Under controlled atmosphere, easily perishable foods such as beef and vegetables are kept longer and fresher. It also helps to deliver food in portion sizes to consumers, significantly minimising wastage of food. Physical damage of food and beverage is prevented where water and other diverse drinks are bottled in plastic packaging, particularly during transportation and shipping. Furthermore, it helps in displaying and detailing data and information about the encased goods to consumers. This includes the use, composition, nutritional value, and safety of the food or drink.

Plastic packaging can be recycled despite that the product easily becomes waste due mostly to its single use. The continued increase in the demand for plastic packaged products through food deliveries and groceries continues to contribute to a consequent increase in plastic waste. Recycling provides a circular solution to this challenge. It helps to divert the waste away from the landfill and conserve plastic resources.

* Ellen MacArthur Foundation. (2017). The new plastics economy: Rethinking the future of plastics and catalysing actions. Ellen MacArthur Foundation,

https://emf.thirdlight.com/file/24/RrpCWLERyBWPZRrwSoRrB9KM2/The%20New%20Plastics%20Economy%3A%20Rethinking%20the%20future%20of%20plastics%20%26%20catalysing%20action.pdf

Plastic is saving and protecting lives

Plastic has contributed enormously to healthcare, particularly due to its ability to protect. It is substantially applied in the health sector, making life safer and the sector cost-efficient. This is validated where plasticsare applied as medical supplies such as surgical gloves, syringes, IV tubing, face masks, and inulin pens. The application of plastics in the healthcare has helped in several ways.

Figure of plastics in the healthcare

Plastic is helping to reduce the necessity to sterilize and reuse materials and equipment, and this limits the transmission of infections and diseases. Safety, and likewise storage, are enabled as it is used to make tamper-proof caps for blister packs, waste bags and medical packaging. This is as a result of its strength. It helps in providing flexibility and comfort, unlike alternative materials used for medical components, such as metal and glass. It benefits the sector in terms of cost efficiency, as medical components can be produced in large quantities as a result of its relatively low costs. Furthermore, it provides reliability, as medical plastic items are largely free from wear and tear, as well as being corrosion free.

The protective capacity of plastic was openly evident during the COVID-19 pandemic. The material was a critical component in the production of personal protective equipment (PPE), which contributed tremendously towards bring the pandemic to an end. Plastic PPE such as masks, gloves, goggles, respirators, and gowns play a core role in protecting health workers during duties. Similarly, the global populace were mandated to protect themselves with face masks while in public places. During the pandemic, health workers globally required about 89 million medical masks, 1.6 million goggles, and 76 million gloves monthly (WHO, 2020).

* WHO. 2020. Shortage of personal protective equipment endangering health workers Worldwide. World Health Organization,

https://www.who.int/news-room/detail/03-03-2020-shortage-of-personal-protective-equipment-endangering-health-workers-worldwide

Join us in creating a sustainable zero plastic waste society - free of plastic pollution. Your generous contributions directly help us to research, advocate and educate.

DonateExplore

Our Impact

Contact

1-7 Muri Okunola Street Victoria Island, Lagos, Nigeria